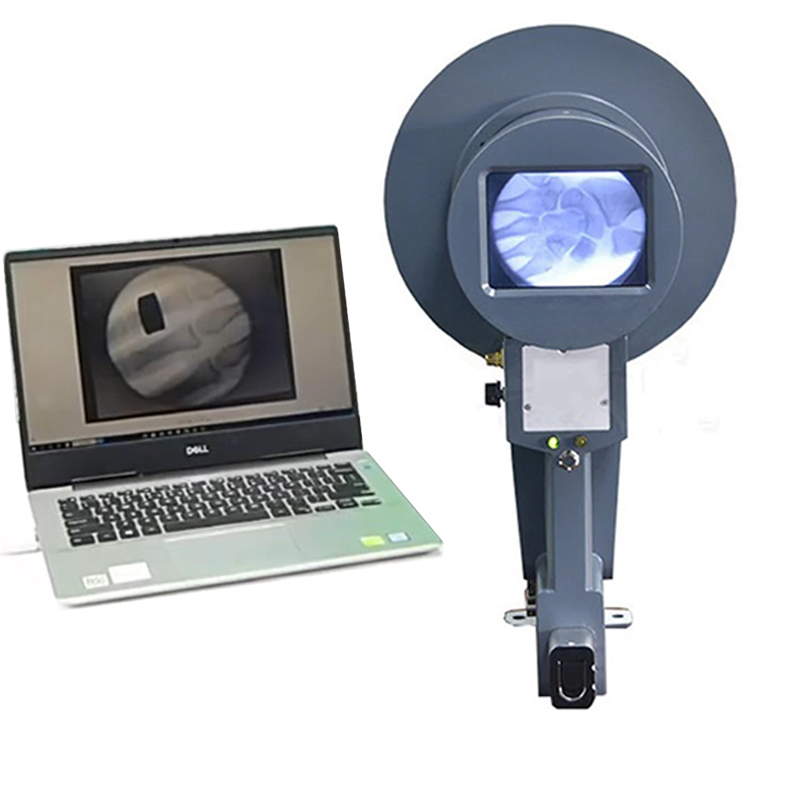

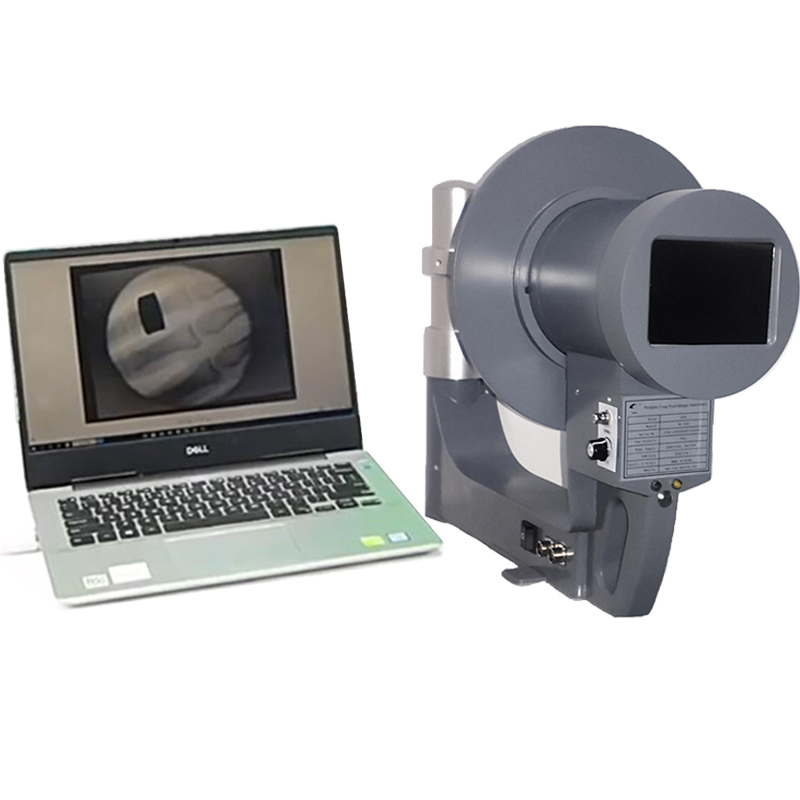

Product Introduction

Features:

- A unique combination of Metal Detector and Checkweigher.

- 100 and 207 Product Memories for optional.

- 3.2'' LCD screen with buttons screen and 7'' Full

touchable screen for optional.

- Diagnostics / Statistic Data Available on Screen.

- Security Level Provided.

- Custom Build Solution.

- Dual Automatic Rejection – one for Metal Detector and

another for Checkweigher.

- Cost Effective and Space Saving Solution.

Applications:

- Pharmaceutical: Bottle line before sealing and capping.

- Food: For non-metallic packing of Snack Food, Spices,

Flour, Ready to Eat, Cream, Meat, Sea

Food, Chopped Vegetable and Confectionary.

- Beverage: Glass / HDPE Bottled product.

- Others: Personnel

Care, Rubber, Garment, Dairy, Baby Care, stationery, and etc.

Specification

| Best Metal Detecting Sensitivity |

Fe: Φ1.5mm Non-Fe: Φ2.0mm Sus304: Φ2.5mm (The actual performance may be subject to working environment and components of the products to be tested) |

| Metal detection tunnel size | 400mm(W)*250mm(H) (Can be customized) |

| Weighing range | 100g-5,000g |

| Conveyor size & material |

Metal detecting section size: 1,200mm(L)*300(W)mm

Weighing

section size: 500mm(L)*300(W)mm Conveyor belt: FDA Food-grade white PU belt with SGS certificate |

| Weighing accuracy | ±1g - ±5g |

| Display resolution |

0.1g |

|

Capacity |

80-120 pieces/min |

| Weighing sensor | ZEMIC |

| Engine | JSCC |

| MS weighing scale module | JZXR |

| Height of the conveyor belt to the ground |

680mm ± 50mm (Can be customized) |

| Display screen |

Weinview 10-inch touchable color screen |

|

Automatic rejectors

|

One pusher rejector for metal detector and another pusher for checkweigher Rejector type: can be customized with Air jet, flap and down model |

| Construction | Stainless steel 304 |

| Temperature | 0 ℃~40 ℃ |

| Hhumidity | 90% Relative humidity (without condensate) |

| Voltage | AC 110~220V (+10%) |

|

Frequency |

50/60 Hz |

| Power | 0.7 KW |

| Plug | EU, BR, US |

Application

Main Components

Manufacturing

Our Customers

Certifications

Pусский

Pусский

+86 13751397283

+86 13751397283