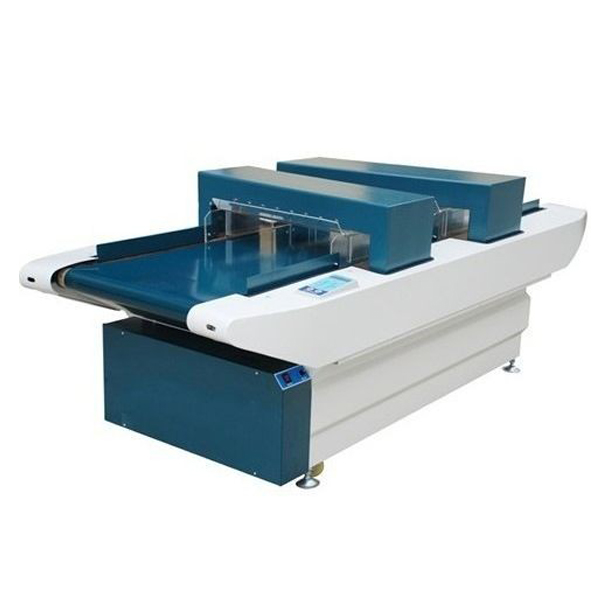

Product Introduction

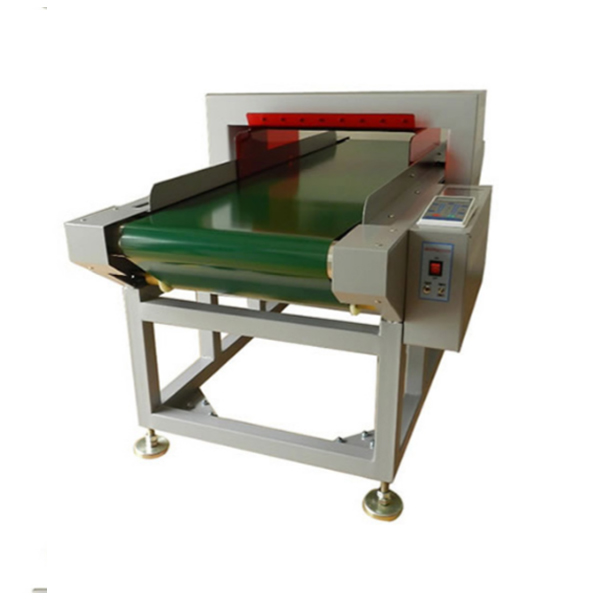

1. The inspection device adopts technology from Japan, imported core parts, and food grade conveyor

2. 8 functions available for option: automatic detection, stepless sensitivity adjustment, counter, auto-sensing start, power saving, protection, automatic conveyor stop or return

3. Detection efficiency of the metal detection equipment reaches 100%. The device can work continuously

4. When there is broken needle or metal items detected, the machine will alert, stop and return to the starting point, and then restart automatically

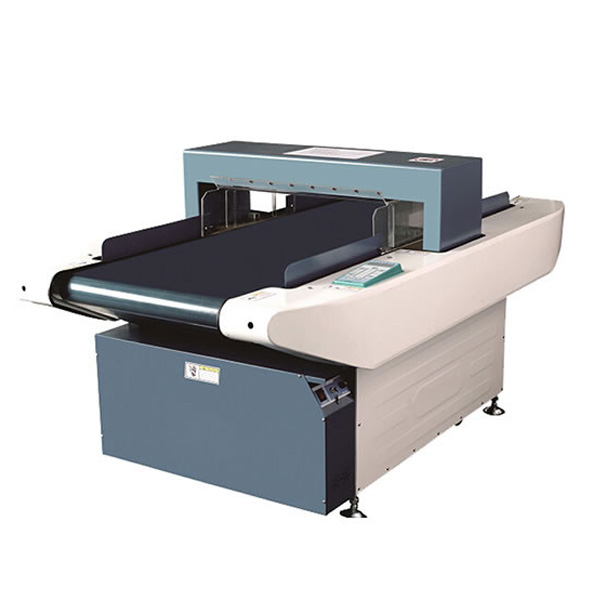

5. Sensitivity is adjusted from 0 to 100 grade by an easily-operated touch panel according to different detection needs

6. Defective products are separated from good ones intelligently. Auto counting function is available

7. The machine is designed to show year, month, and time

8. With an intelligent control system, users can make the machine detect the duration and distance of rewinding

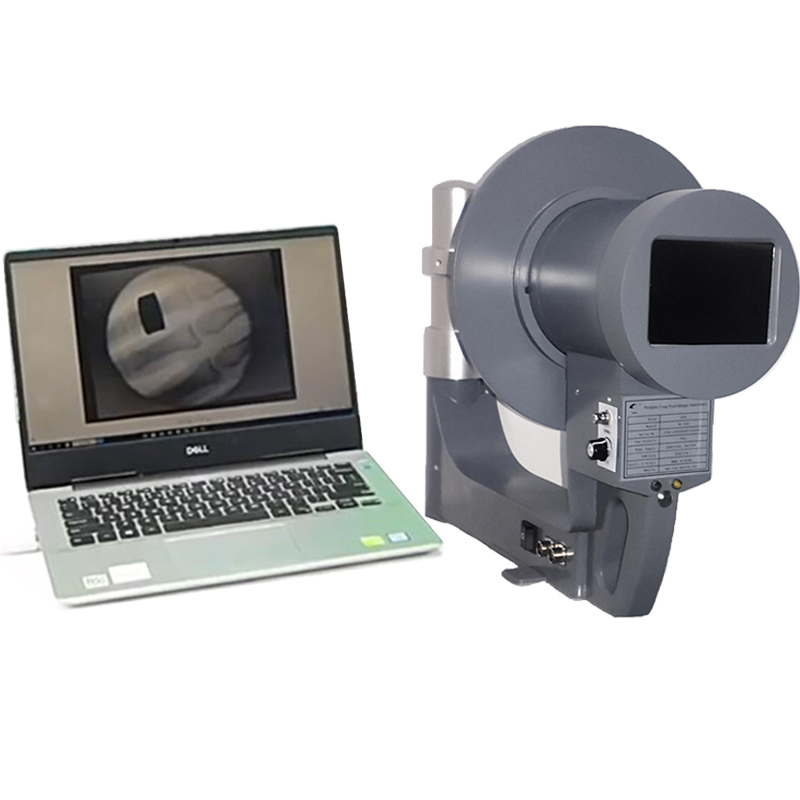

9. The dual detection system doubles sensitivity of the machine comparing with other metal detecting machineries

10. B and C type testing function available; manual or automatic settings

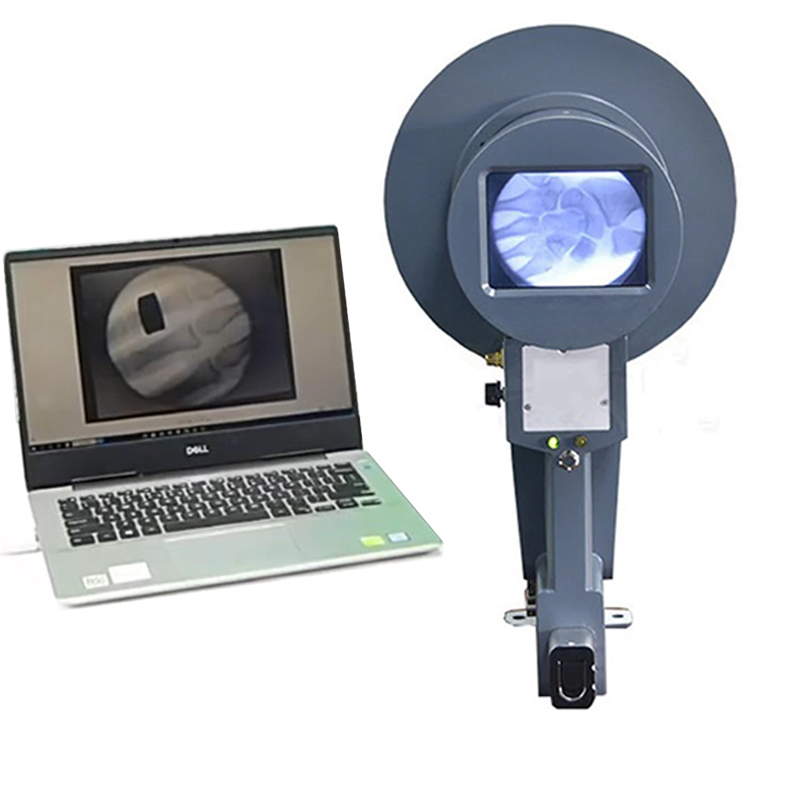

11. The light helps show exactly where the broken needles are

Needle Detector Applications

XR-630 metal detector is widely applied in industries where there is a demand for detecting metal foreign bodies, like cloth manufacturing, rubber toy processing, show making, bedclothes, metal buttons, zipper head, chemical processing, food production, medicine manufacturing, and meat and fishery processing, etc.

Specification

| MODEL | XR-630K | |||

| Detection approach | electromagnetic induction | |||

| Detection sensitivity (mm) | ≥FeØ0.7 | ≥FeØ0.8 | ≥FeØ1.0 | ≥FeØ1.2 |

| Detection height (mm) | 100 | 120 | 150 | 200 |

| Detection width | 600mm (customized) | |||

| Detection adjustment | 0-10 level | |||

| Alerting method | audible alert, shutdown, go backwards, and then restart | |||

| Voltage | Ac220V 50-60Hz | |||

| Power | 100W | |||

| Dimension | 1650×1050×900mm (L×W×H) | |||

| Weight | about 180KG | |||

Application

Main Components

Manufacturing

Our Customers

Certifications

Pусский

Pусский

+86 13751397283

+86 13751397283