Product Introduction

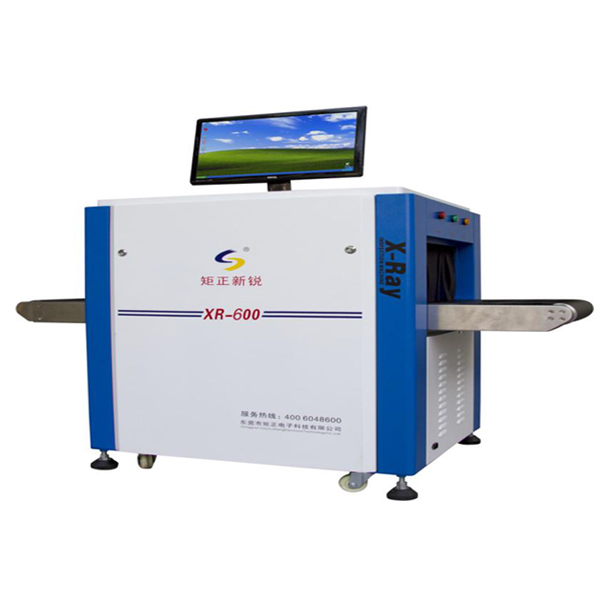

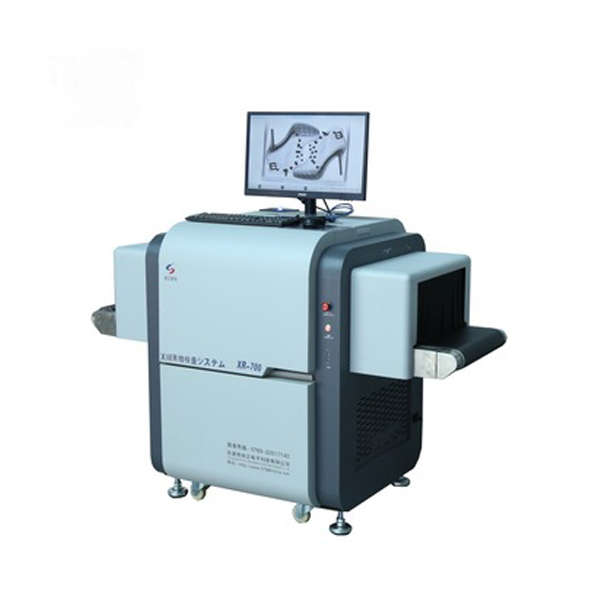

1. XR-600W security check equipment employs an X-ray image processing system. The FPGA chip with high-speed algorithm, high-resolution large-screen display, extended functionality, accompanied with user-friendly human-machine interface provides a high inspection accuracy

2. Its processor with high speed adopts fully-embedded digital signal processing system

3. Multi-mode 0.4 × 2mm CMOS image sensor from Japan is adopted for the X-ray detecting equipment

4. X-ray tube made in the US is power and current adjustable

5. It is of high inspection accuracy and can clearly display the smallest debris, foreign bodies, and even 1.2mm-diameter metal wires

2. Its processor with high speed adopts fully-embedded digital signal processing system

3. Multi-mode 0.4 × 2mm CMOS image sensor from Japan is adopted for the X-ray detecting equipment

4. X-ray tube made in the US is power and current adjustable

5. It is of high inspection accuracy and can clearly display the smallest debris, foreign bodies, and even 1.2mm-diameter metal wires

6. Inspection speed is adjustable, with the standard value to be 12m/min (600 bag/h)

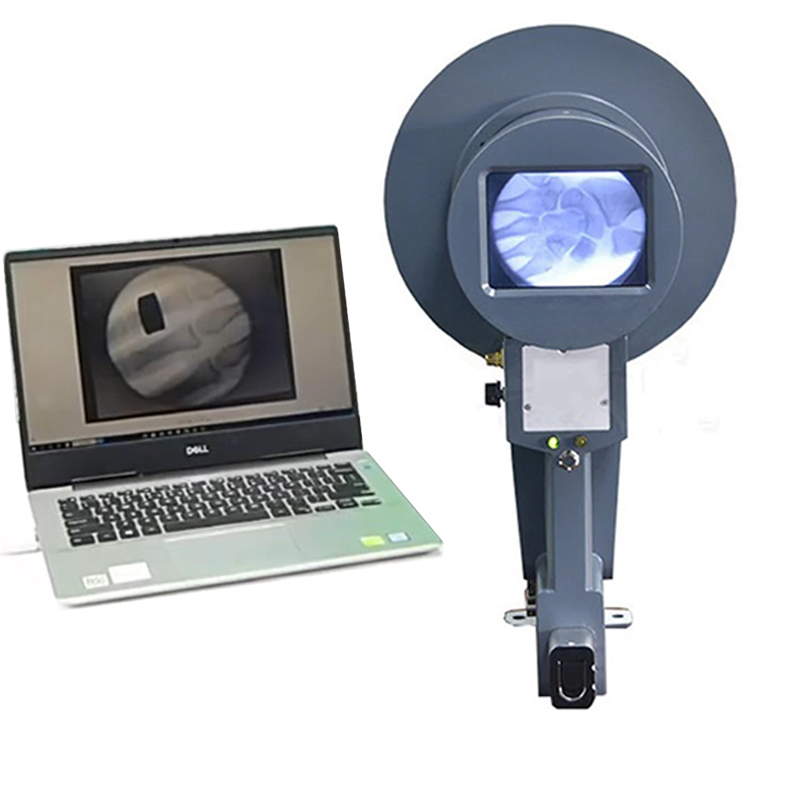

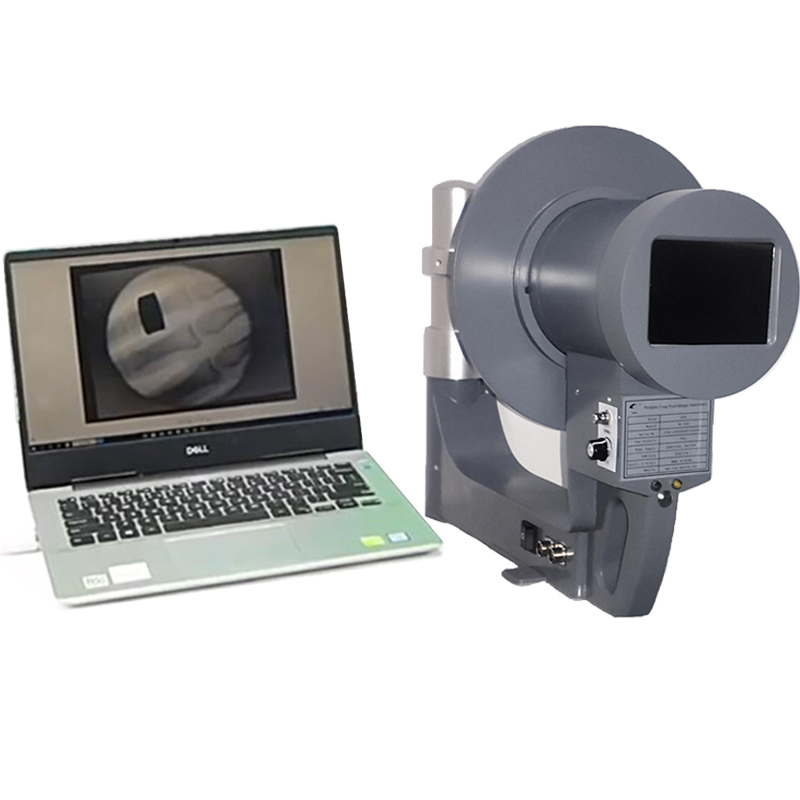

X-Ray Inspection System Videos

Specification

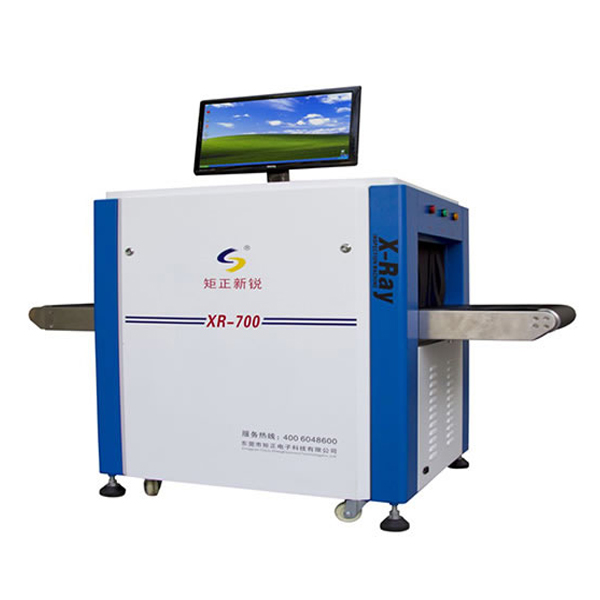

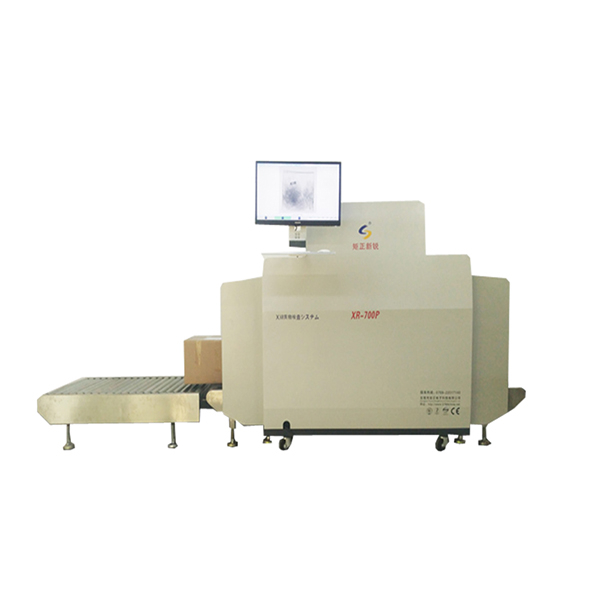

| Passageway size | 505mm (W) * 305mm (H) |

| Machine dimension | 1650*780*1200mm |

| Conveyor height | 700-800mm |

| Conveyor speed | 0.22 m/s |

| Rated conveyor load | 110 kg |

| X-ray volume for single inspection | < 1.5 μ GNy |

| X-ray penetration | 43mm-thick steel plates |

| X-ray leakage | 0.752 μ Gy/h; in line with national health and safety requirements on radiation devices |

| Voltage | AC220V, 50 ± 3Hz |

| X-ray tube voltage | KV 100~160 (adjustable) |

| Power | 0.3kw/h |

| Working environment | temperature: 0℃~60℃; humidity: 20%~90% (non-condensable gas) |

| Noise | ≤ 57dB |

Application

Main Components

Manufacturing

Our Customers

Certifications

Pусский

Pусский

+86 13751397283

+86 13751397283