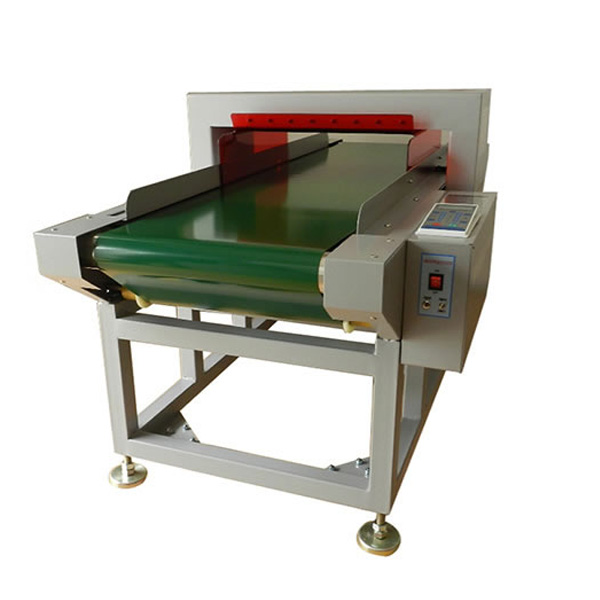

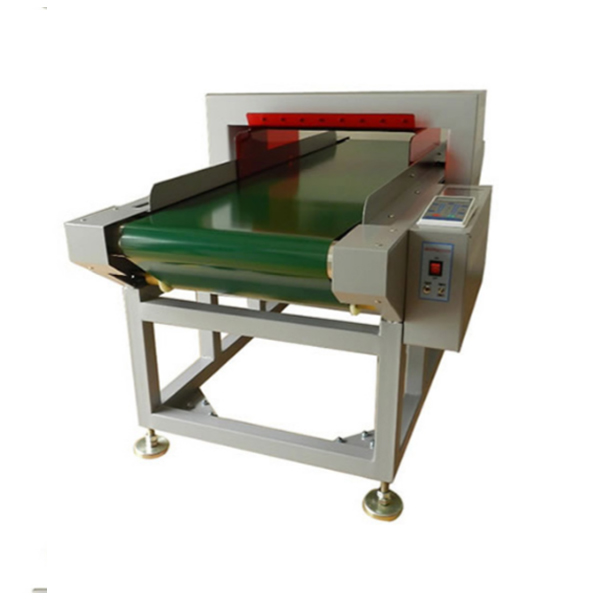

Product Introduction

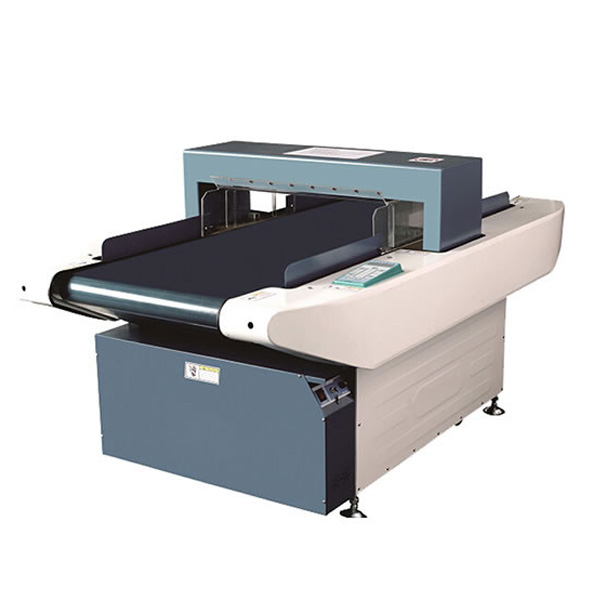

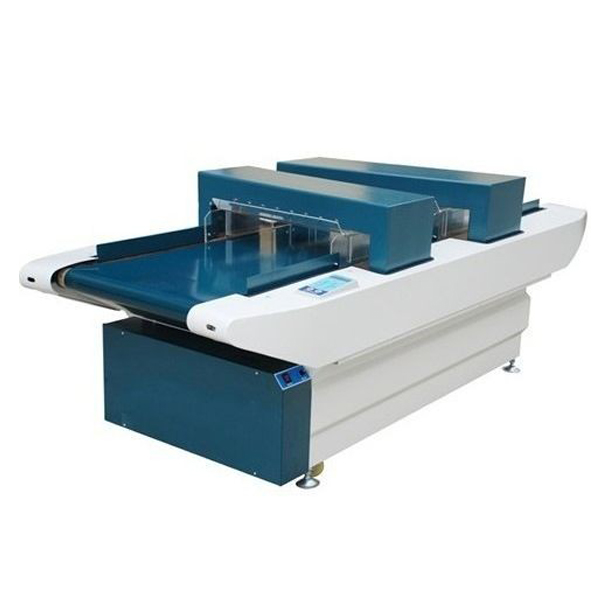

XR-8500 needle detector is extensively applied in detecting magnetic metal impurities in cloth, toys, baby products, clothing accessories, shoes, socks, fabric, non-woven towels, blankets, gloves, and crafts, etc.

Main Features

1. XR-8500 metal detector shows streamline exterior design. Carbon steel structure accompanied with painting treatment endows the equipment with stable performance and long service life.

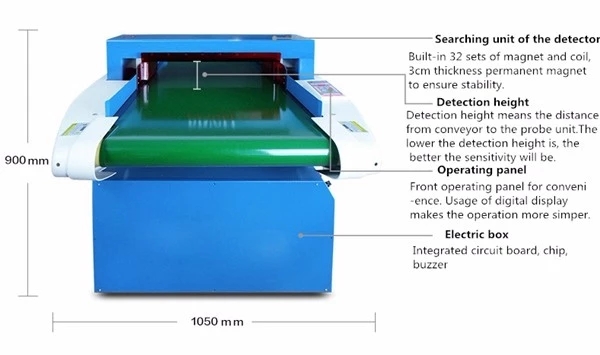

2. Core part from Japan, conveyor belt from Netherlands, 32-bit chip, and digital circuit design with the newest international technique

3. Sensitivity of the detector is controlled by computer from 1 to 120 grade. Parameters are shown on LCD screen

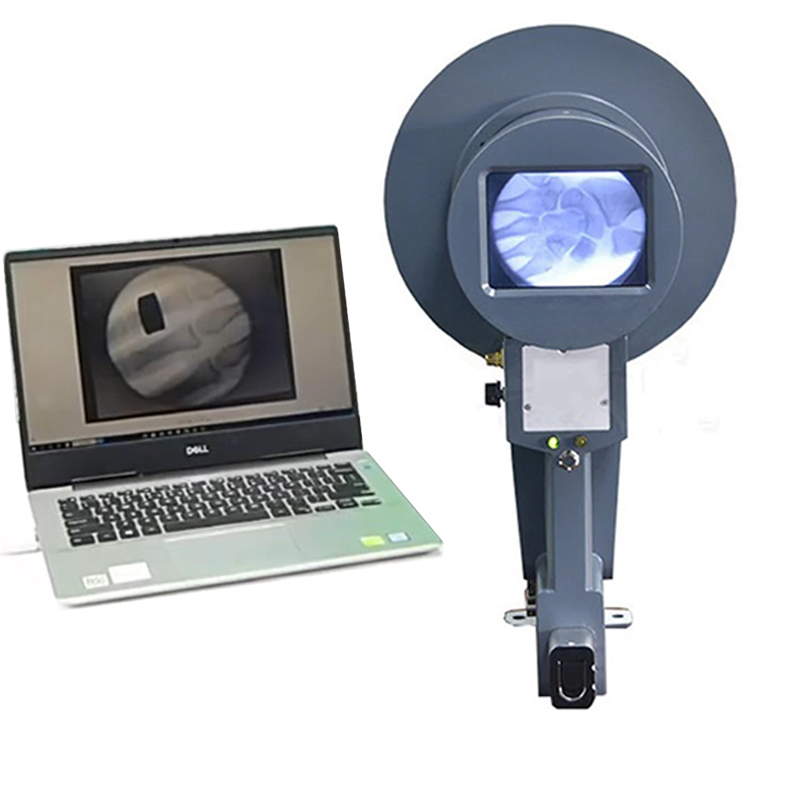

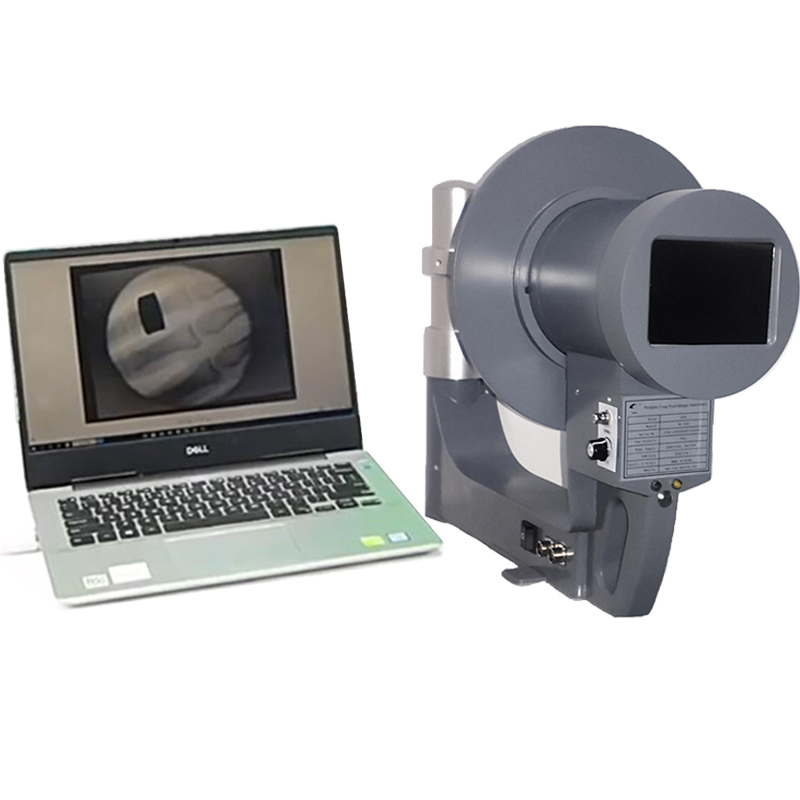

4. Location of the broken needles or ferromagnetic metal is showed accurately

5. A snsing device is employed for the metal detection instrument to eliminate the interference from iron oxide

6. Quantity of the qualified, the unqualified, and the total is recorded intelligently. Detective products are separated out from the good ones

7. The load bearing frame is able to run stably with a load of 30kg

8. Unique color identification mode

9. Audible alert; rewind manually or automatically

10. Sensitivity is guaranteed by safety lock device

Specification

| MODEL | XR -8500 | ||||

| Detection approach | electromagnetic induction, digital circuit processing | ||||

| Sensitivity | ≥ Fe Φ 0.8 | ≥ Fe Φ 1.0 | ≥ Fe Φ 1.2 | ≥ Fe Φ 1.5 | ≥ Fe Φ 2.0 |

| Detection height | 120 | 150 | 200 | 250 | 300 |

| Detection width | 500mm (customizable) | ||||

| Detection adjustment | 1-120 grade | ||||

| Alerting method | audible alert, shutdown, go backwards, and then restart | ||||

| Power supply | AC220V 50-60Hz | ||||

| Pated output | 120W | ||||

| Machine Size | L1850mm × W950mm × H1000mm | ||||

| Net weight | 280KG | ||||

Application

Main Components

Manufacturing

Our Customers

Certifications

Pусский

Pусский

+86 13751397283

+86 13751397283