Product Introduction

XR-500D series is used for detecting contaminants inside small- and medium-sized packaged products.

Foreign bodies include all metal contamination (ferrous, non-ferrous, and SUS), ceramic, stones, glass, bones, hard rubber, and hard plastic — even in products wrapped in aluminum foil or metallized film.

Contaminants are detectable based on their density.

The greater the density, the easier they can be detected.

This is why we typically use X-ray inspection systems to detect even the tiniest contaminants.

Specification

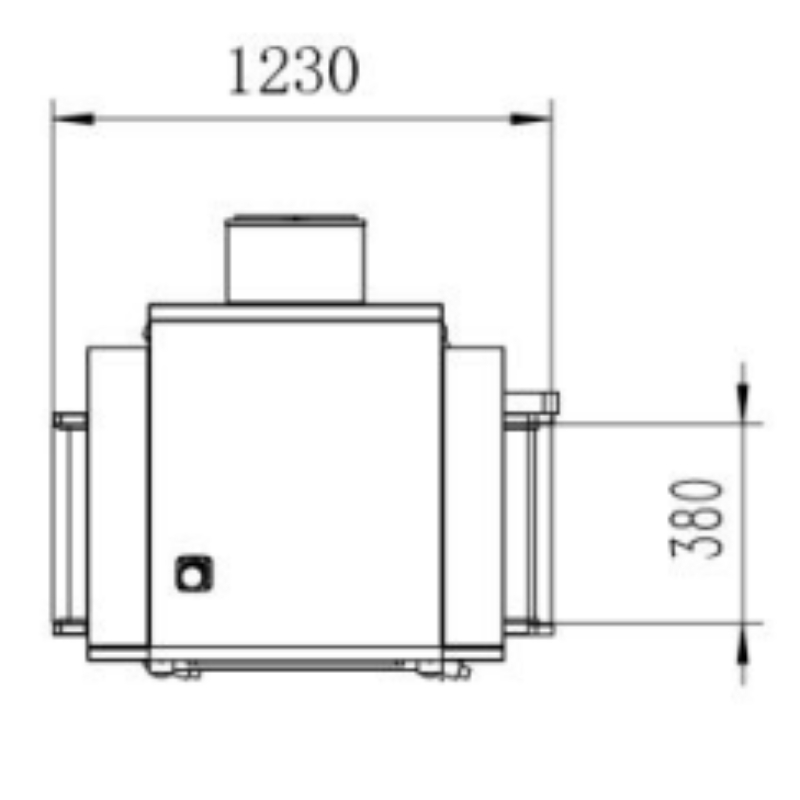

| Model: | XR-500D |

| X-ray Source: | Standard:210w,80kv.(optional: 350w,100kV) |

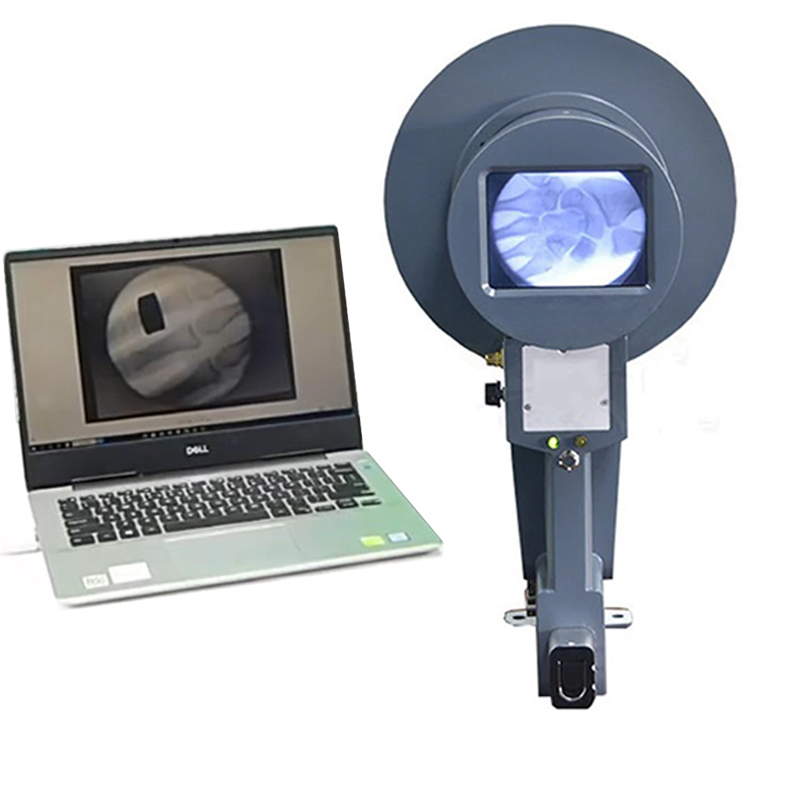

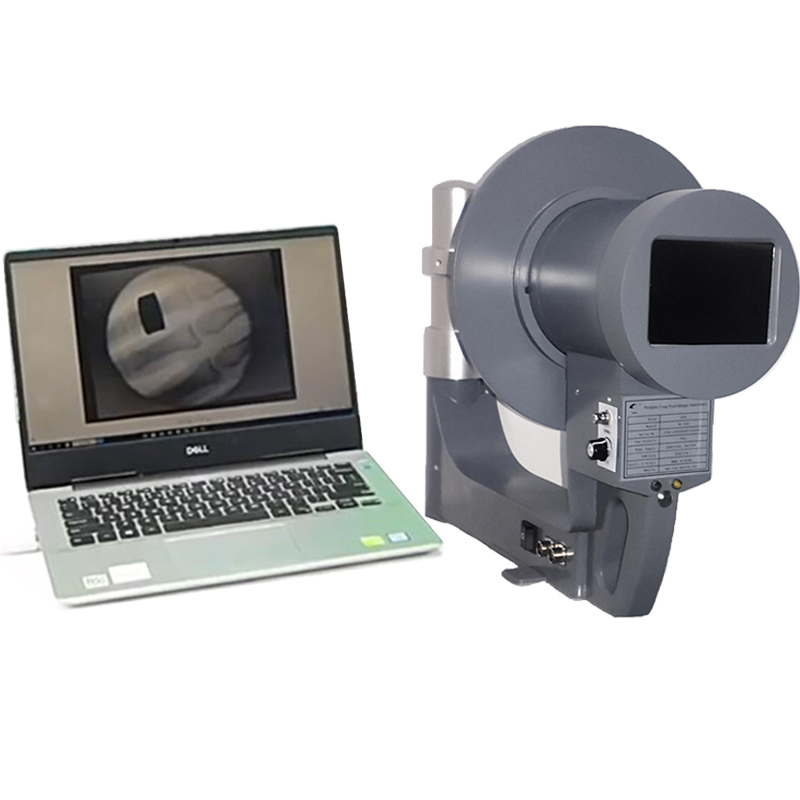

| X-ray Beam Direction: | From the top |

| Detector: | 0.4mm |

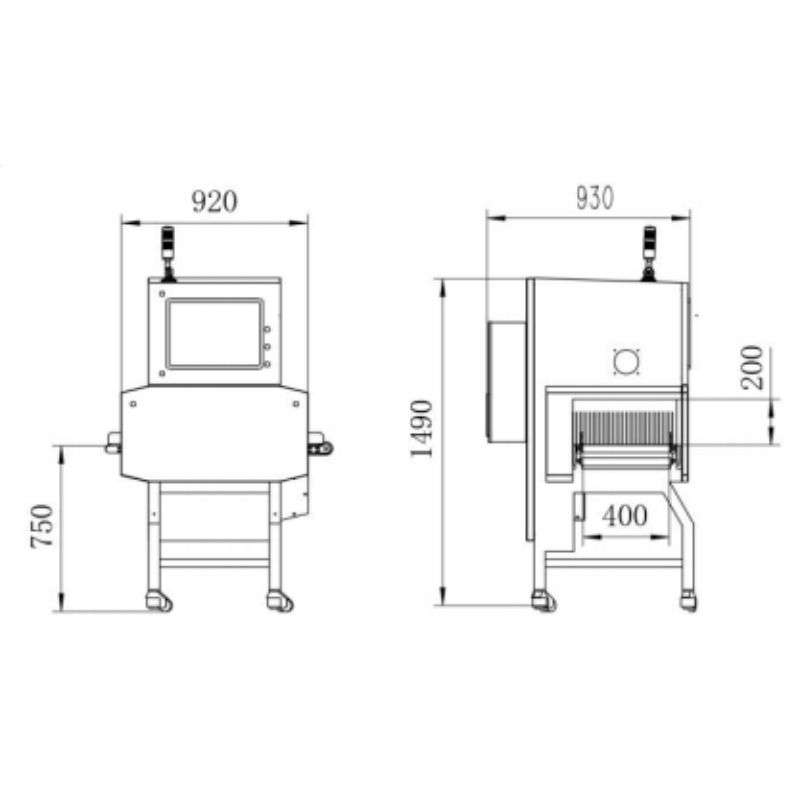

| Detection Tunnel Size: | 400mm (w)x 200mm(H).Customized order is acceptable |

| Max. Detection Accuracy without product(210W X-ray Source): | SUS:≥φ0.4mm,Ceramic:≥φ 1.0mm,Glass:≥1.0mm |

| Conveyor Speed: | 20-60 m/min |

| Bearing Capacity: | Standard:10 kg ( Customized order is acceptable) |

| O/S: | Win 10 |

| Software: | JZXR X-ray Inspection Software |

| Connectivity: | LAN port & USB port |

| Screen: | 21.5 inch full color touchable screen |

| Parameter Adjustment: | Auto Setting & Manual Setting |

| Operation Language: | Chinese & English |

| Reaction to defectives: | buzzer and red light alarm once foreign body is detected |

| Automatic Rejection System | Optional (Please check below for details) |

| Material of construction: | SUS 304 |

| Surface Treatment | Mirror Polished / Brushed |

| Cooling Mode: | Industrial cooling fans & industrial A./C |

| Working Environment: | temperature:-5℃-40℃:humidity: 30-90%RH (no condensation) |

| Power Supply: | AC220V+10% 50/60Hz |

Application

Main Components

Manufacturing

Our Customers

Certifications

Pусский

Pусский

+86 13751397283

+86 13751397283