Product Introduction

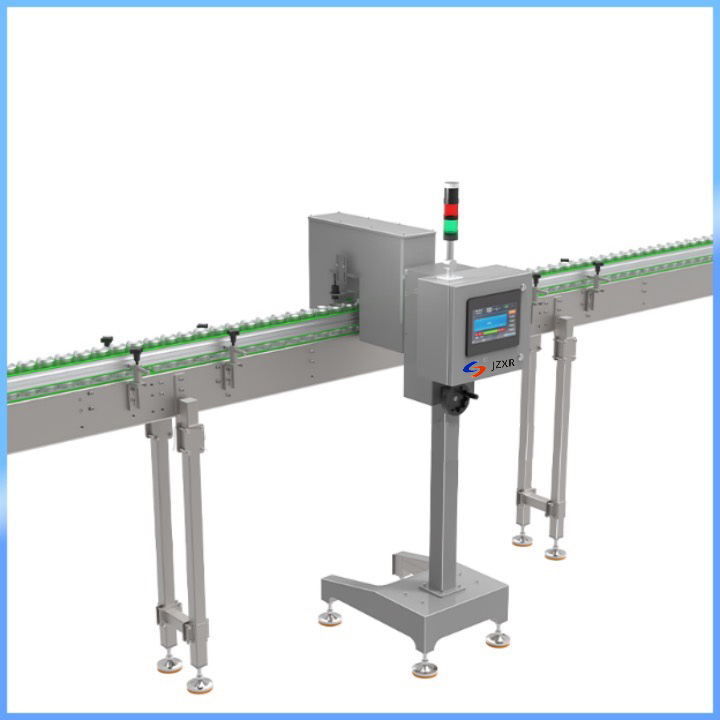

X-ray Inspection System for Large Food Product Packaging XR-100D-6550

Specification

| Model | XR-100D-6550 |

| X-ray source | 350W 80KV |

| Tunnel size(W*H) | 650*500mm |

| Max sensitivity | SUSl ballΦ0.4mm, SUS wireΦ0.2*2mm,CeramicsΦ1.0mm, GlassΦ1.0mm |

| Conveying speed | 10-50m/min |

| Screen | 17'' Full touchable screen |

| Interface for data | LAN port,USB port |

| Working environment |

Temperature:-10-40ºC(Cooling:industrial air condition), Humidity:30%-90%,No frost(humidity control:dehumidifier) |

| X-ray leakage | <1µSv/hour |

| Protective mode | Protective soft curtain(removable) |

| Alarm | Standard: Sound and light alarm |

| Optional: Stop / Rejection system | |

| Power supply | AC220V ±10% 50/60Hz,1.5kVA Max |

| Material | SUS304 |

| Conveyor load | Standard: Max 5kg |

| Customized: > 5kg |

Application

Juzheng X-ray Inspection System for Large Food Product Packaging XR-100D-6550 is used for detecting contaminants inside of the small packaged products. Metal and non-metal impurities include ferrous, non-ferrous, stainless steel, glass, ceramic, stone, bones, had rubber and hard plastic, even for products wrapped in aluminum foil or metallised film and etc. The foreign object is detectable by its density. The greater density they have, the easier they can be found. That is why we normally use X-RAY inspection system to detect even the most tiny contaminants.

Main Components

Manufacturing

Our Customers

Certifications

Pусский

Pусский

+86 13751397283

+86 13751397283