Product Introduction

1. Comprehensive detection: it can detect foreign substances with high density, such as metal, glass, stone, bone, ceramic, hard rubber, hard plastic, etc.; The properties of products are applicable to a wide range of applications, such as plastic packaging, aluminum foil packaging, glass filling, metal canning, bulk testing, etc.

2. High-speed detection: the world's leading computing and processing capacity, with the detection speed of up to 120 meters per minute, greatly meeting the production efficiency.

3. Excellent detection accuracy to ensure product quality and protect user brand reputation.

4. Rich development functions: multi-point omission detection, defect detection (product defect, package defect) screening section detection, liquid level height detection, high-speed elimination detection, remote control, integrated real-time management and other functions.

5. Simple operation: 15-inch touch screen operation, self-learning function, intuitive and simple operation experience. Automatically save the detection picture for users to track and trace.

2. High-speed detection: the world's leading computing and processing capacity, with the detection speed of up to 120 meters per minute, greatly meeting the production efficiency.

3. Excellent detection accuracy to ensure product quality and protect user brand reputation.

4. Rich development functions: multi-point omission detection, defect detection (product defect, package defect) screening section detection, liquid level height detection, high-speed elimination detection, remote control, integrated real-time management and other functions.

5. Simple operation: 15-inch touch screen operation, self-learning function, intuitive and simple operation experience. Automatically save the detection picture for users to track and trace.

6. Green and environmentally friendly design concept: all the accessories meet the food requirements, and the radiation leakage amount meets the us FDA and the European Union CE standard.

Specification

| Max detection accuracy | lead: φ 0.2mm; stainless steel ball: φ 0.4mm; ceramic ball: φ 0.8mm; bone: φ 0.8mm; glass: φ 1.0mm | |

| Inspection dimension | max width | 180mm |

| max height | 285mm | |

| Max dimension allowed to pass | 350*310mm (width*height) | |

| Conveyor belt width | 200mm | |

| Conveyor height | 850±30mm | |

| Conveyor speed | 10-90m/min | |

| Bearing capacity | 10Kg | |

| X-ray output | 40-150kVp/2-7.5mA | |

| X-ray leakage | < 3μSv/h | |

| Detector | linear scanning | |

| X-ray direction | double light | |

| Pixel size | 0.4mm | |

| Monitor | 15-inch LCD touch screen | |

| Operation method | by touch screen | |

| Software | Intellisense X-ray Inspection System | |

| System | Windows 7 | |

| Port | USB | |

| Parameter setting | manually/automatically | |

| Shell material | SUS304 | |

| Conveyor material | PU belt | |

| Air conditioner | internally-circulated industrial air conditioner; automatic temperature control | |

| Protection method | removable protective curtain | |

| Cleaning | cleaning job is done conveniently for the conveyor belt can be removed without tool | |

| Power supply | AC220/230V, 50/60Hz | |

| Environment | temperature: 5-35℃; humidity: 30-85%RH (no condensation) | |

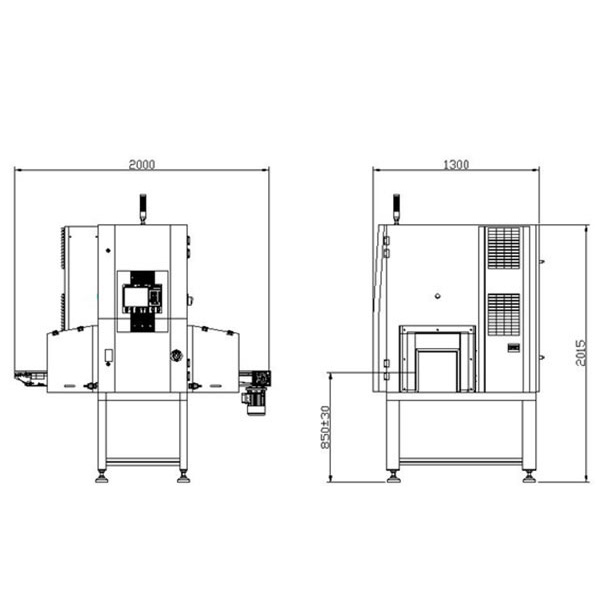

| Machine dimension | 2000*1300*2015mm (L*W*H) | |

| Machine weight | 600Kg | |

Application

Main Components

Manufacturing

Our Customers

Certifications

Pусский

Pусский

+86 13751397283

+86 13751397283